Lidding foil

Lidding foil is used extensively in dairy and food sector. They are designed to seal and peel from various base materials such as PP, PS, PET, Paper, etc. Film foil lidding is an essential element that must not be overlooked when strategizing your product’s packaging design. Multi-layered film foil lidding has many advantages compared to its counterpart- heavy-gauge foils, such as clear and easy peeling, higher barrier performance, better branding with more printing color option and it is more sustainable.

Main Categories of Dairy Foil

Die-cut foil lids

lidding foil roll

Non metal sealing film

Induction sealing gasket

Die-cut foil lids

Die-cut aluminium foil lids, is the lidding foil is cut into matching pieces according to the size and shape of the cup or bottle top, which is used for automatic high-speed sealing machine or semi-automatic sealing equipment. It is mainly used for sealing dairy, sauces, dip, honey, cup instant noodles and other products.

- Structure : Alu/Heat seal lacauer or film

- Size and shape : diameter from 21mm to 144mm, please contact us for mold table. New mold can beoipen on request.

- Printing : Single color printing, multi-color printing, pattern printing, up to 9 colors

- Embossing : Normally orange peel(worm) texture

- Packaging : 1000pcs/box, 10 to 36boxes/carton

Lidding Foil Roll

Aluminium lidding foil roll, as the name implies, is the sealing film used in roll type. Generally speaking, narrow width is used to seal plastic bottles, aluminum foil and heat sealing film is thick. Wider sealing foil is used to seal joined-cup yogurt, butter, or dips.

- Structure : Alu/Heat seal lacauer or film, PET/Alu/PE, PET/VMPET/PE

- Width : 30mm to 600mm

- Printing : Single color printing, multi-color printing, pattern printing, up to 9 colors

- Packaging : 1 roll or several rolls/carton, standard food grade packaging

Non metal sealing film

Non – metal sealing film, low price with exquisite printing. Because there is no metal layer, the shading performance is not very good, therefore it is used for sealing products with short shelf life requirements. There are three categories: transparent, frosted and paper film.

- Structure : PET/PE, Paper/PE

- Width : 30mm to 600mm

- Printing : Single color printing, multi-color printing, pattern printing, up to 9 colors

- Packaging : 1 roll or several rolls/carton, standard food grade packaging

Induction sealing gasket

Induction sealing gasket, that is, the use of aluminum foil sealing machine to heat the aluminum foil sealing gasket, so that the aluminum foil sealing gasket thermal sealing layer is hot melting, under certain pressure conditions so that the thermal sealing layer and the bottle mouth bonded, so as to achieve the role of bottle mouth sealing. Suitable for PET,PE,PP,PVC,PS,ABS and glass bottles.

- Structure : PET/EPE/Alu/Sealing layer, Paper/EPE/Alu/Sealing layer

- Size and shape : diameter from 20mm to 144mm. New mold can be open on request.

- Printing : Single color printing, multi-color printing, pattern printing

- Texture : Flat or teture as required

- Packaging : 1000 to 10000pcs/carton

What you care about lidding foil

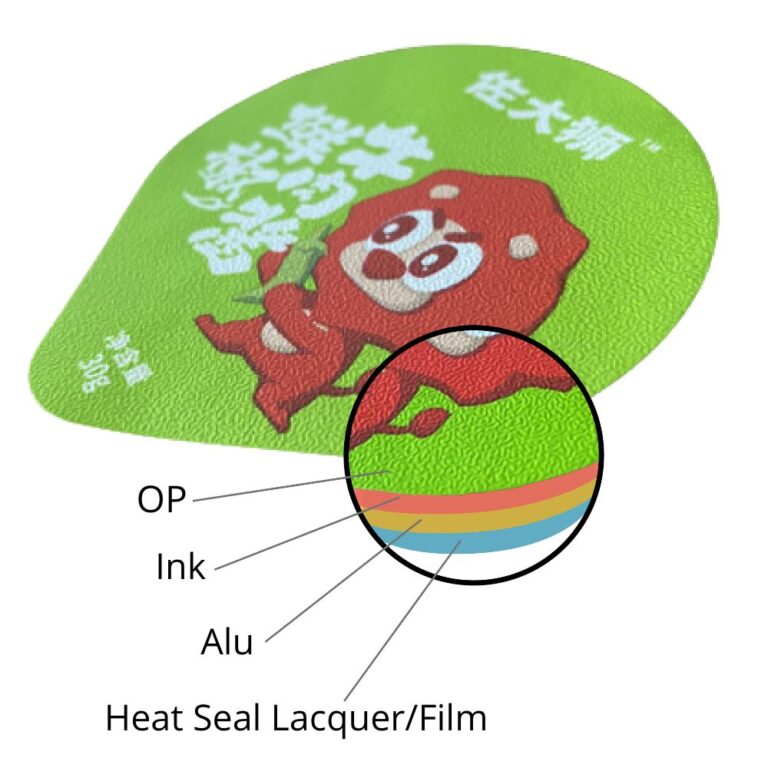

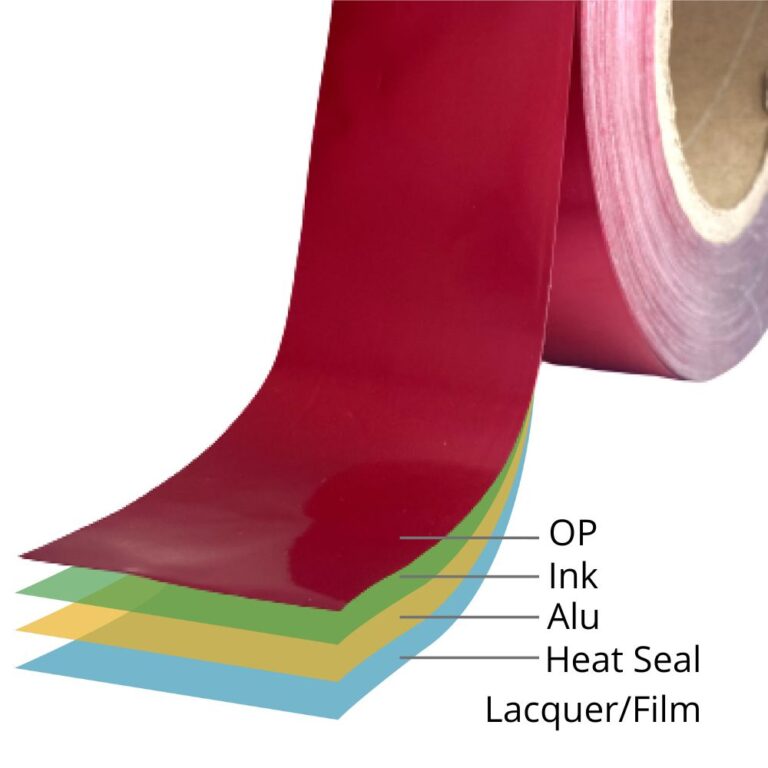

Structure of Lidding foil

Heal seal lidding foil, whether die-cut foil lids or lidding foil roll, is aluminum foil laminated with plastic film or coated with heat seal lacquer, then it has heat sealing performance.

After lamination or coating, when heating to a certain temperature (usually 160 to 220℃,the macromolecule crosslinking of the heat seal layer will be changed, producing adhesive properties, and then under certain pressure ,bonding with the containers such as plastic trays, cups or bottles, to achieve the purpose of sealing.

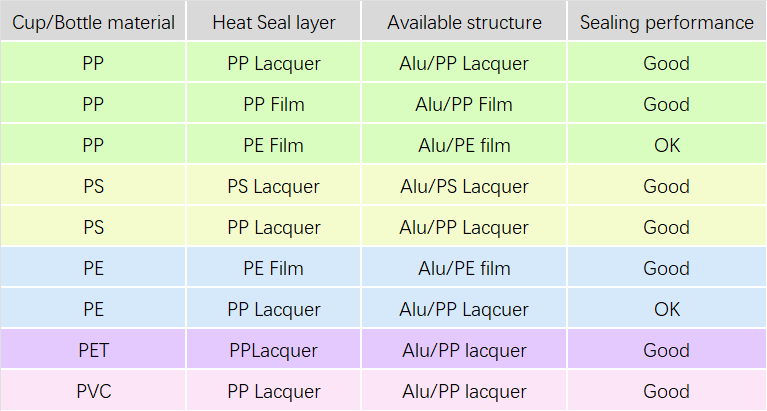

Different cup or bottle materials, need seal with corresponding film or lacquer.

In order to match containers of different materials, as well as to meet the requirements of various printing, tensile, strength, high temperature retort etc., the lidding foils have different structures.

The following table is the matching heat sealing layer material and the corresponding lidding foil structure of containers of different materials.

Of course, not every match can achieve perfect heat sealing effect. Please choose the appropriate lidding foil structure according to the product and sealing requirements.

Beside the container material, the characteristics of the contents, such as ph value, alcohol, corrosion and so on, will affect the effect of sealing more.

In addition, equipment temperature, pressure, speed and operation stability will affect the sealing effect and the shelf life of the contents.

If you want to achieve the desired sealing solution, please do not hesitate to contact us.

Want to know more?

Send us a message if you have any questions or request a quote. I will reply within 24 hours.

- +86 18906431372(WhatsApp/Wechat)

- +86 13953315846

- [email protected]

If you do not mind, please do leave your phone number, because it is easier to get in touch with you.

If you do not receive my reply in time, please check the spam box, because sometimes my reply is there.

If your needs is urgent, please contact me directly on WeChat or Whatsapp.