Flexiable package laminated foil

After aluminium foil is laminated with plastic or paper, it not only maintains good barrier property, but also has superior mechanical properties. Laminated aluminium foil is an important category of flexible packaging, widely used in food and beverage, agricultural products, pharmaceuticals, personal care products and etc.

Main categories of laminated foil

Laminated aluminium foil roll

Aluminum paper composite film

Flexible packaging laminated film

Pouch

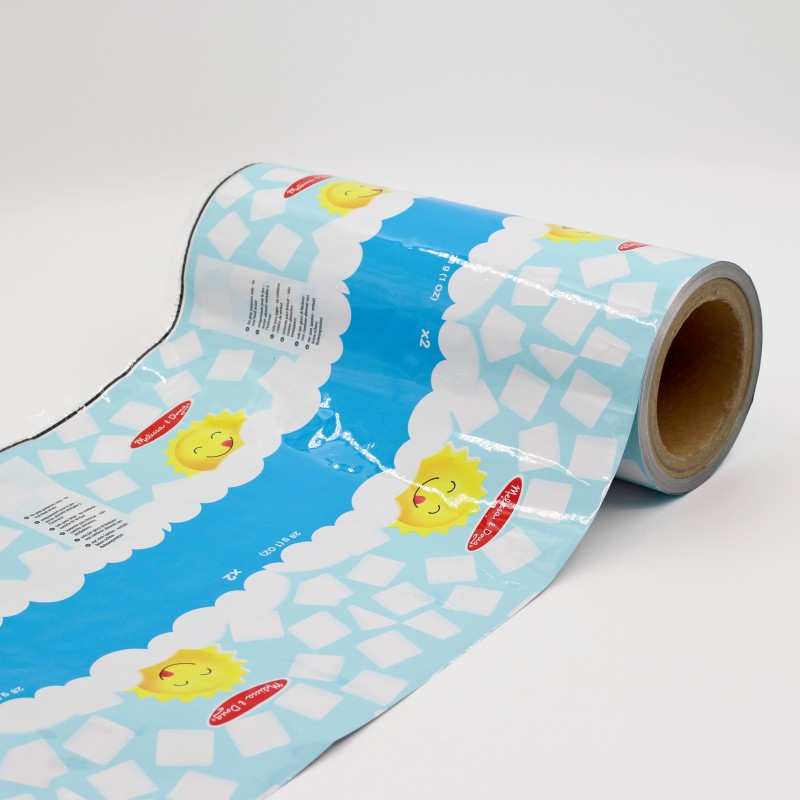

Laminated aluminium foil roll

Laminated aluminium foil refers to aluminum foil composite with PET, BOPP, PE or other materials, it can be two layers, three layers or multi-layer structure according to request, after printing and slitting into a certain width, it can be used fin automatic packaging machine, to pack solids, granules, powder, gel and liquids.

- Structure: PET/Alu/PE, BOPP/Alu/PE, PET/AL/CPP

- Thickness: Customized

- Width : 90 to 1000mm

- Printing : up to 9 colors

- Packaging : 1 roll/box, with/without blade. Roll set, several rolls/box.

Aluminum paper composite film

For the needs of product design, printing, and packaging products, aluminum foil can also be composite with paper to achieve more suitable stiffness, thickness, strength and other physical properties.

- Structure: Paper/Alu/PE, Paper/AL/CPP, other structure customized

- Thickness: Customized

- Width : 90 to 1000mm

- Printing : up to 9 colors

- Packaging : 1 roll/box, with/without blade. Roll set, several rolls/box.

Flexible packaging roll film

For the products with low shielding requirements, VMPET, paper, or other plastic materials can be used instead of aluminum foil. This flexible packaging laminated film is used for automatic packaging machine to package products that are not sensitive to light. Compared with laminated aluminum foil , this film is lower cost and economical.

- Structure: BOPP/PE or CPP, PET/PE or CPP, BOPP or PE/VMCPP, NY/PE, PET/VMPET/PE, BOPP/PET/PE or CPP, NY/VMPET/PE

- Thickness: Customized

- Width : 90 to 1000mm

- Printing : up to 9 colors

- Packaging : 1 roll/box, with/without blade. Roll set, several rolls/box.

Pouch

In addition to the laminated foil roll for automatic packing machine, we can also supply a variety of styles of pouches.

- Material: Laminated foil, paper laminated foil, flexible film

- Type: 3 sides seal pouch, center seal pouch, Spout pouch and etc

- Size: Customized

- Printing : up to 9 colors

- MOQ : 10000 to 200000 according to size

What you care about laminated foil

Applications

instant foods

Frozen foods

- PET/PE

- BOPP/PE, BOPP/CPP

- PET/VMPET/CPE, BOPP/VMPET/CPE

Medicine, personal care and home care products

The laminated film used in the packaging of pharmaceuticals, personal care and home care needs good barrier performance, which can avoid light, retain fragrance and moisture-proof. It mostly use the laminated film containing aluminum foil layer to barrier oxygen and light. At the same time, the packaging of personal care and home care products also needs exquisite printing and gorgeous texture to attract consumers.

Tea and coffee

Most important thing is to maximize the retention of aroma. Use metalized films or aluminum foil layer laminated film bag package coffee or tea , insulate coffee or tea from oxygen and prevent it from oxidizing in the air.

Snacks and chips

In order to retain a crisp dry taste and rich flavor of snacks and chips, packaging materials need to be able to block oxygen, water and light. Therefore, it is necessary to use the composite film containing aluminum foil for packaging. Aluminum foil has superior light barrier performance, which can avoid the snacks and chips been oxidation and deterioration under the ultraviolet light, resulting in soft taste and abnormal flavor.

Want to know more?

Send us a message if you have any questions or request a quote. I will reply within 24 hours.

- +86 18906431372(WhatsApp/Wechat)

- [email protected]

If you do not mind, please do leave your phone number, because it is easier to get in touch with you.

If you do not receive my reply in time, please check the spam box, because sometimes my reply is there.

If your needs is urgent, please contact me directly on WeChat or Whatsapp.